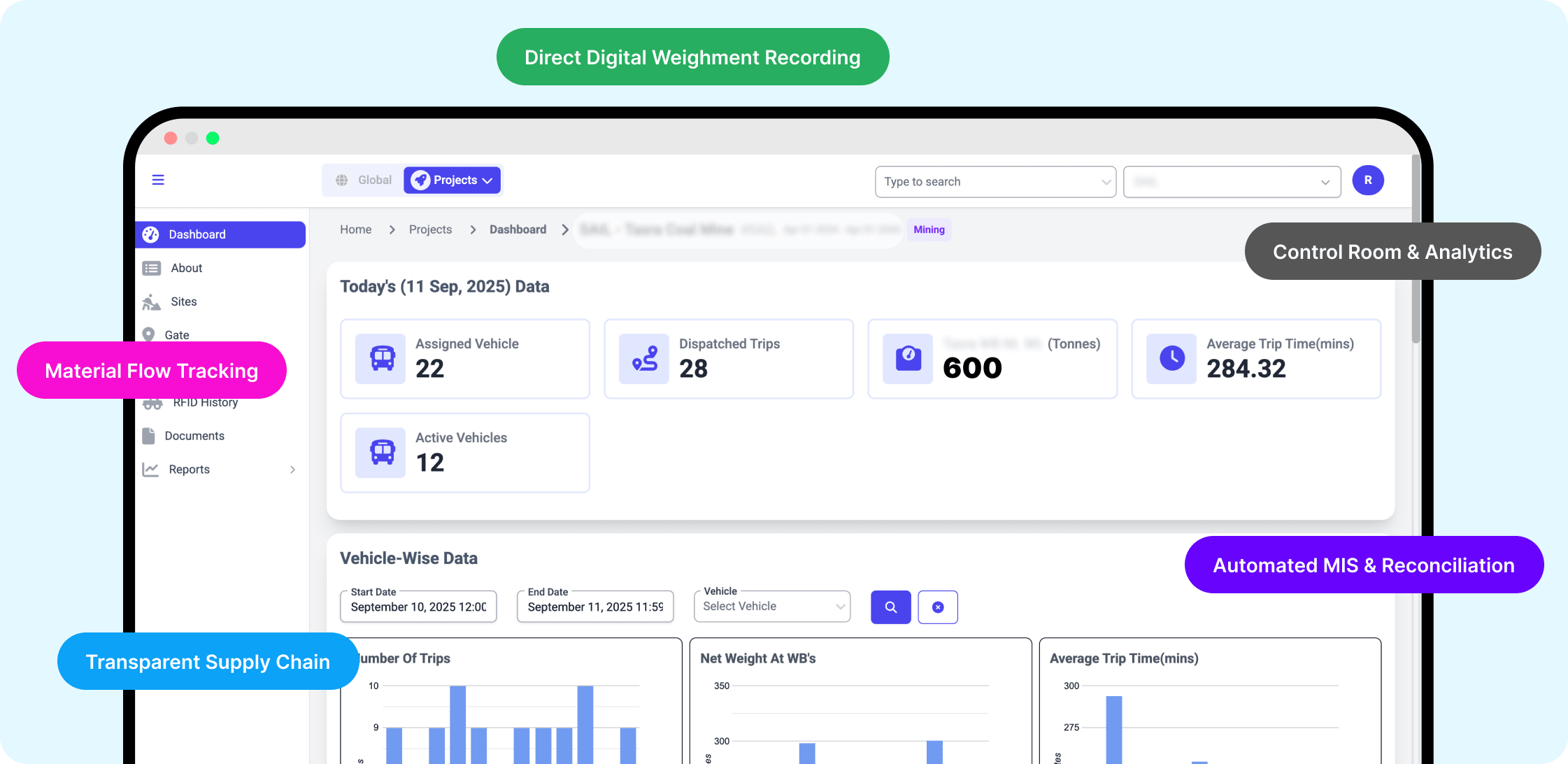

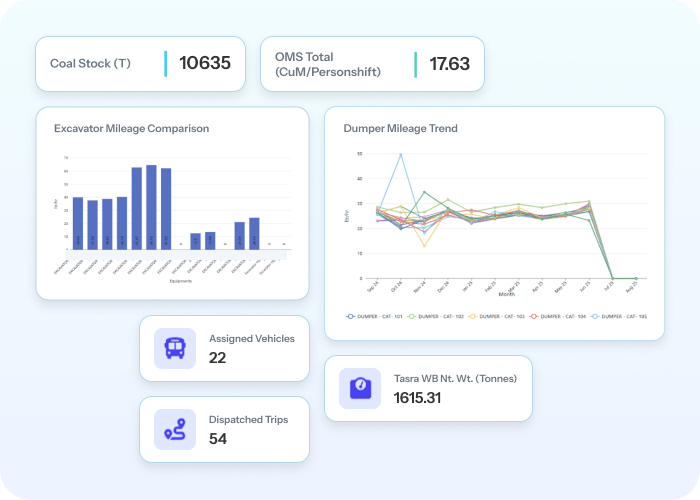

From fragmented workflows to AI-powered control—digitally transforming mining and infrastructure for real-time insights, smarter decisions, and safer operations

Mining and infrastructure teams grapple with manual inefficiencies, maintenance bottlenecks, safety risks, and siloed data. InstaDigin’s Digital Operations Control tackles these head-on with advanced software, predictive models, analytics, and automation—helping you boost efficiency and productivity while enabling safer practices.

Built on InstaDigin’s Six-Pillar Intelligence Model:

GPS and payload monitoring to reduce fuel consumption and improve efficiency.

Automated planning, execution tracking, and post-blast analytics.

Dynamic resource allocation and shift management.

Geo-fencing, automated vehicle allocation, and real-time route optimization.

Unified hub for 24/7 monitoring and proactive decision-making.

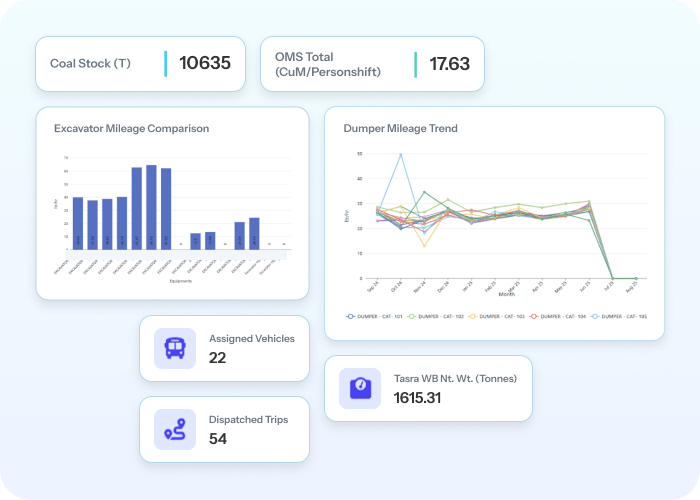

Real-time visibility of critical operational metrics and KPIs.

Connects with your existing systems (ERP, GPS, etc.) to create one unified, non-disruptive environment.

Enhanced efficiency, reduced downtime, and optimized resource utilization.

Real-time monitoring and predictive analytics reduce operational risks.

Comprehensive, real-time insights enable faster, informed decisions.

Automated and optimized workflows lower maintenance and fuel expenses.

Easy-to-access records and proactive compliance tracking.

Optimize resources and reduce your carbon footprint.

Real-time monitoring and proactive alerts prevent accidents before they occur, improving worker safety and reducing risk.

We’ve gathered all the important info right here. Explore our FAQs and find the answers you need.

The system uses AI to analyze real-time video feeds and data from IoT sensors, detecting unsafe conditions such as unauthorized personnel in hazardous zones or equipment malfunctions. It then sends instant alerts for immediate action.

Yes, InstaDigin seamlessly integrates with your current systems, including ERP, GPS tracking, fleet management, and task monitoring, providing a unified approach to safety.

This solution is designed for high-risk industries such as mining, construction, logistics, and manufacturing, where safety is critical, and real-time monitoring can prevent accidents and streamline operations.

Drones provide real-time aerial footage, helping monitor areas that are difficult to access or visually assess, such as hazardous zones, water bodies, and road widths. This enhances situational awareness and enables proactive decision-making.

Begin your digital transformation journey now — Connect with our experts.