In today’s complex operations, you’re drowning in data but starving for actionable decisions. Project managers battle budget overruns, downtime, and underutilized assets—forced into a constant cycle of firefighting. Relying on gut instinct or historical data for multi-million-dollar decisions is a risk you can’t afford.

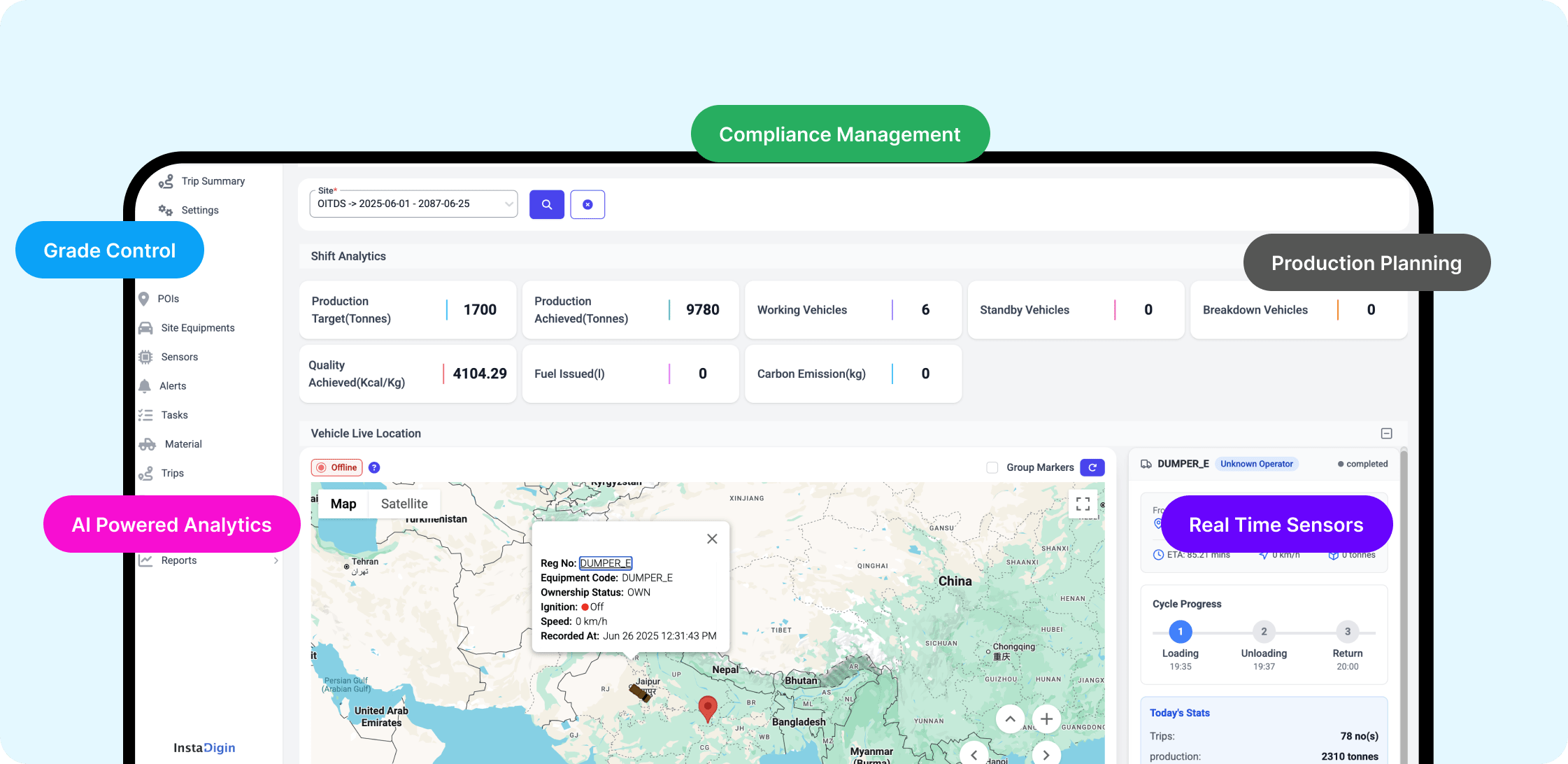

InstaDigin’s Optimization Models close the gap between hindsight and foresight. We transform your operational data into a predictive engine—shifting you from reactive firefighting to proactive, AI-led decision-making.

Run thousands of "what-if" scenarios in a risk-free virtual environment to predict the impact of decisions on your KPIs.

Receive clear, AI-driven instructions on routing, sequencing, and blast design to maximize output and cut costs.

Optimize your entire value chain, from blasting to dispatch, by letting our AI detect how decisions in one area impact all others.

Ask plain-language questions about your operations and get instant, AI-generated answers, reports, and trend analyses.

Predict equipment failures before they occur using IoT data, enabling proactive maintenance that minimizes downtime.

Intelligently assign the right resources to the right task in real-time, eliminating idle assets and bottlenecks.

Model and optimize your operations for both profitability and sustainability, reducing your carbon footprint and fuel costs.

Remove idle time and keep every asset earning. Continuous, shift-by-shift monitoring locks utilisation at its peak.

Simulate the full workflow digitally to expose clashes early. Fix them in the model so real-world schedules stay intact.

Optimise engine hours and routes to curb fuel burn. Predictive maintenance cuts surprises and extends component life.

Match crews and machines to the highest-value tasks in real time. Data-driven dispatching trims waste and boosts throughput.

Track emissions at the source and benchmark against goals. Actionable insights help you shrink carbon and prove compliance.

Live dashboards that turn raw data into next steps. Allows managers to collaborate better and raise operational standards.

We’ve gathered all the important info right here. Explore our FAQs and find the answers you need.