About Client

Ashoka Buildcon Ltd., a Fortune India 500 company and one of the nation’s leading infrastructure developers, operates a vast and diverse fleet of high-value equipment across numerous large-scale projects. To drive a new era of operational excellence, they partnered with InstaDigin to bridge a critical visibility gap by integrating their central SAP ERP system with key field data streams.

The Challenge: Data Silos and a Lack of Centralized Visibility

Before partnering with InstaDigin, Ashoka Buildcon faced significant operational hurdles rooted in fragmented data. While their SAP system held a wealth of information on thousands of assets, it was disconnected from the day-to-day physical operations on the ground. This led to key inefficiencies:

- Fragmented Data: Crucial information was split between SAP (shift logs, maintenance records) and the physical location of assets, with no single platform to view them together.

- Difficult to Track Equipment Status: Managers lacked a centralized dashboard to quickly assess fleet-wide availability, utilization, production, and breakdown status, making proactive decision-making difficult.

- Inefficient Asset Allocation: Without a clear, consolidated view of which equipment was where and how it was being used, optimizing allocation across sprawling job sites was a constant challenge.

- Lack of Actionable KPIs: While data existed in SAP, it wasn’t processed or visualized in a way that provided immediate, actionable insights for site managers, maintenance heads, or financial controllers.

The Solution: A Centralized Dashboard for Fleet Intelligence

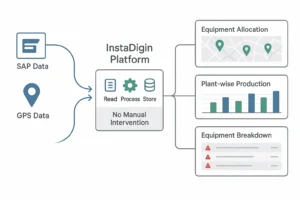

Ashoka Buildcon selected InstaDigin to serve as their data integration and visualization partner. InstaDigin deployed its cloud-based intelligence platform to create a unified digital command center for fleet management, built by integrating two key data sources:

- SAP Data Integration: Shift log information for more than 4000 machines was automatically fetched from Ashoka Buildcon’s SAP system to an FTP folder on a daily basis.

- GPS Data Integration: To provide location-based visibility for critical assets, real-time GPS tracking was implemented for 300 key machineries.

Our platform automatically reads, processes, and stores data from both sources. This combined data powers a suite of powerful, role-based dashboards, providing a single source of truth for fleet operations, including:

- Equipment Allocation Dashboard

- Plant-wise Production Dashboard

- Equipment Breakdown Dashboard

- Equipment Availability and Utilisation Dashboard

The Results: Scalable Automation and Data-Driven Clarity

The InstaDigin platform provided Ashoka Buildcon with a scalable and automated way to turn raw data into actionable intelligence. The tangible outcomes of the project established a new standard for operational visibility:

- Centralized GPS Tracking: Gained live location visibility for 300 critical machineries, improving allocation and security.

- Automated SAP Data Processing: Integrated and processed daily shift log information for over 4000 machines, creating a comprehensive operational database.

- Fully Automated Workflow: The platform successfully automated the entire data pipeline—from reading and processing to storage and dashboard creation—without any manual intervention, eliminating reporting delays and human error.